- English

- Sales & Support:+86-15015013003

| Place of Origin: | China |

| Brand Name: | MSTPACK |

| Certification: | BPI Certificate, BRC, DIN, ABA |

| Model Number: | PCB040 |

| Minimum Order Quantity: | 10000 |

|---|---|

| Price: | US$ 0.02-0.55 / pcs |

| Packaging Details: | Carton |

| Delivery Time: | 10-15days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 100000 tons/year |

| MATERIAL: | Kraft Paper / PE | COLOR: | Up to 10 colors |

|---|---|---|---|

| SIZE: | Customized | SURFACE HANDLE: | Digital Printing |

| FREE SAMPLES: | Available | TYPE: | Stand Up Pouch |

| USAGE: | Coffee, Tea, Snack, Chocolate, Cookie, Candy, Nuts, Other Food | SEAL & HANDELING: | Zipper Top |

| PORT OF SHIPPING: | Jiangmen | FAST DELIVERY: | 7-10 Work Days |

| HIGH LIGHT: | Coffee Packaging Bags | ||

Airtight seals in coffee packaging bags play a pivotal role in preserving the freshness, flavor, and quality of coffee beans from the moment they are roasted until they reach the consumer's cup. These seals are a critical component in the design of coffee bags, and their effectiveness can significantly impact the overall coffee experience. In this detailed explanation, we will delve into the importance, mechanisms, materials, and benefits of airtight seals in coffee packaging.

The primary purpose of airtight seals in coffee packaging is to protect the coffee beans from external factors that can lead to flavor degradation and spoilage. The following factors highlight the significance of airtight seals:

Coffee Packaging Bags Oxygen Barrier: Coffee beans release carbon dioxide gas for a period after roasting, known as degassing. Airtight seals prevent oxygen from entering the bag, which can lead to oxidation and the development of stale or rancid flavors in the coffee.

Coffee Packaging Bags Moisture Protection: Moisture is an enemy of coffee beans, as it can cause them to become moldy or degrade in quality. Airtight seals prevent moisture from infiltrating the packaging, maintaining the beans' optimal moisture content.

Coffee Packaging Bags Aroma Retention: Coffee is valued for its aromatic compounds, which contribute to its rich and complex flavor profile. Airtight seals help preserve these volatile aromas, ensuring that the coffee retains its unique scent and flavor until it's brewed.

Coffee Packaging Bags Shelf Life Extension: Airtight seals significantly extend the shelf life of coffee, allowing consumers to enjoy freshly roasted beans for an extended period.

|  |

Coffee packaging bags are more than just vessels to store coffee; they are critical in preserving the beans' freshness, flavor, and aroma. Heat sealing, a widely used sealing method, plays a pivotal role in ensuring that coffee remains at its peak from the roastery to the coffee cup. In this detailed explanation, we will explore the intricacies of heat sealing in coffee packaging.

Advantages of Heat Sealing:

Coffee Packaging Bags Effectiveness: Heat sealing provides a highly effective and reliable airtight seal, preventing the ingress of oxygen, moisture, and contaminants into the coffee bag.

Coffee Packaging Bags Cost-Efficiency: It is a cost-effective sealing method that can be employed in high-volume coffee packaging processes.

Coffee Packaging Bags Customization: Heat sealing allows for customization of seal designs and can be used on various types of coffee bags, including flat bags, gusseted bags, and stand-up pouches.

Durability: The resulting heat seal is durable and resistant to tampering, ensuring the integrity of the packaging during handling and transportation.

Coffee Packaging Bags Environmental Benefits: In many cases, heat-sealed coffee bags use materials that are recyclable, contributing to sustainable packaging practices.

Coffee Packaging Bags Quality Control in Heat Sealing:

Achieving a perfect heat seal in coffee packaging is essential to maintaining product quality. To ensure consistency and reliability, manufacturers employ quality control measures such as:

Coffee Packaging Bags Temperature Control: Precise control of the heating element's temperature is crucial to achieving a consistent seal. Deviations in temperature can lead to weak seals or even bag damage.

Coffee Packaging Bags Pressure Regulation: Maintaining consistent pressure during the sealing process is equally vital. Too much pressure can damage the bag, while too little pressure may result in an inadequate seal.

Coffee Packaging Bags Seal Inspection: Manufacturers often employ automated systems to inspect seals for defects, such as incomplete sealing or contamination. Any bags with substandard seals are removed from the production line.

Coffee Packaging Bags Operator Training: Skilled operators are trained to monitor the heat sealing process and make necessary adjustments to ensure quality and consistency.

Coffee Packaging Bags Heat Sealing and Coffee Freshness:

The primary goal of heat sealing in coffee packaging is to preserve the freshness of the coffee beans by creating an airtight environment. By preventing oxygen from entering the bag, heat sealing helps retain the coffee's flavor, aroma, and overall quality. Freshly roasted coffee beans emit carbon dioxide gas, and heat sealing ensures that this gas is trapped within the bag, preserving the beans' freshness without the risk of bag rupture.

|  |

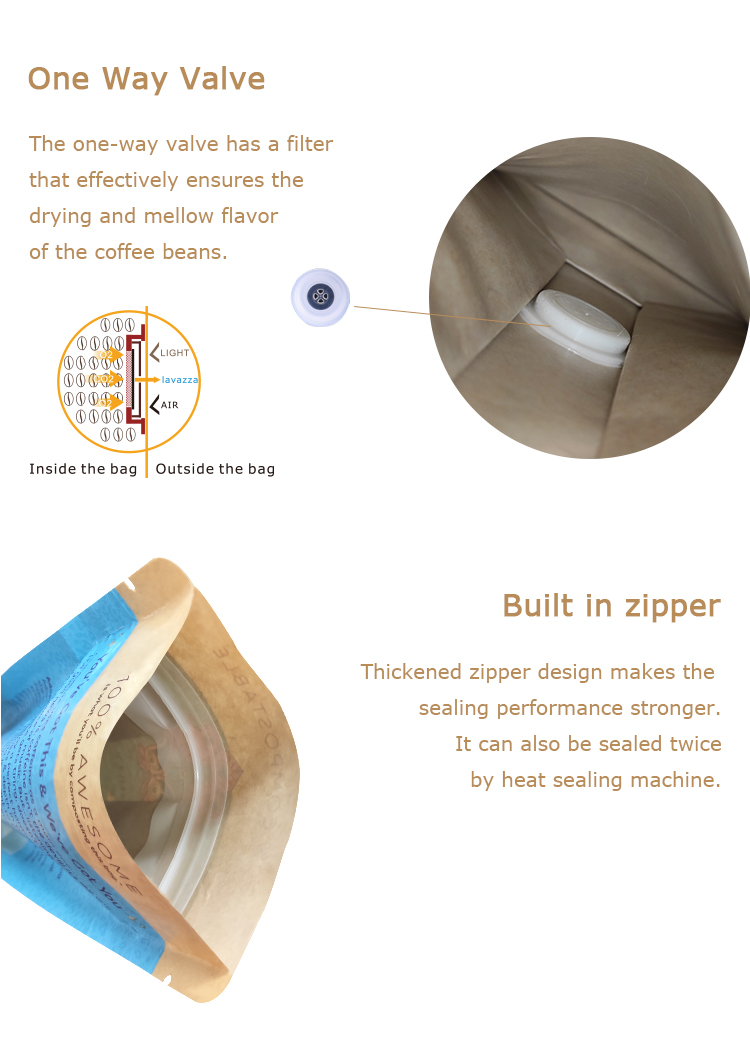

Coffee Packaging Bags Zipper seals:

Zipper seals have become a common feature in coffee packaging bags, especially for brands that prioritize convenience and freshness retention. These resealable seals are designed to allow consumers to open and close the bag multiple times while maintaining the coffee's freshness and aroma. In this detailed explanation, we will explore the intricacies of zipper seals in coffee packaging bags.

Coffee Packaging Bags Mechanism of Zipper Seals:

Zipper seals operate on a straightforward yet effective mechanism:

Coffee Packaging Bags Interlocking Mechanism: Zipper seals consist of two interlocking plastic strips with complementary profiles. When the zipper is closed, these strips align and engage along the length of the bag's opening.

Coffee Packaging Bags Airtight Gasket: Typically, a zipper seal includes an airtight gasket made of materials like silicone or rubber. When the zipper is closed, the gasket compresses against the bag's inner surfaces.

Coffee Packaging Bags Closure: As the user slides or presses the zipper together, the interlocking mechanism engages, creating an airtight barrier. The gasket compresses, ensuring that the seal is airtight.

Coffee Packaging Bags Resealing: After the consumer opens the bag and extracts coffee, they can easily reseal it by closing the zipper. This action reestablishes the airtight seal, maintaining the coffee's freshness.

Coffee Packaging Bags Advantages of Zipper Seals:

Zipper seals offer several notable advantages for coffee packaging:

Coffee Packaging Bags Consumer Convenience: Zipper seals provide a user-friendly way for consumers to reseal the bag tightly, ensuring that coffee remains fresh between uses. The ease of use encourages consumers to keep the coffee in its original packaging.

Coffee Packaging Bags Extended Freshness: By allowing consumers to reclose the bag, zipper seals contribute to extended freshness and shelf life for the coffee. This reduces waste and enhances the consumer's coffee experience.

Coffee Packaging Bags Versatility: Zipper seals are versatile and can be used with various types and sizes of coffee bags, including flat bags, gusseted bags, and stand-up pouches.

Coffee Packaging Bags Enhanced Branding: Coffee brands can utilize the resealable feature as an additional branding element, highlighting the bag's convenience and commitment to freshness.

Coffee Packaging Bags Quality of Zipper Seals:

The effectiveness of zipper seals in preserving coffee freshness depends on the quality of the seal and the materials used. To maintain quality and consistency, manufacturers employ various measures:

Coffee Packaging Bags Material Selection: The choice of materials for both the zipper strips and the airtight gasket is critical. High-quality, food-safe materials that are resistant to moisture and oxygen are essential.

Coffee Packaging Bags Seal Strength: The strength and integrity of the zipper seal must be consistent across all bags. Manufacturers use precise machinery and quality control checks to ensure that each bag is sealed correctly.

Coffee Packaging Bags Leak Testing: Some manufacturers conduct leak tests to confirm the airtightness of the seal. This can involve using specialized equipment to check for any leaks or compromised areas.

Coffee Packaging Bags Operator Training: Skilled operators are responsible for monitoring the zipper sealing process and making adjustments as needed to ensure quality and consistency.

Coffee Packaging Bags Zipper Seals and Sustainability:

Zipper seals can also contribute to sustainability efforts. When consumers can easily reseal the bag, they are less likely to transfer the coffee to another container or use disposable clips or ties. This reduces the need for additional packaging and minimizes waste.

|  |

Coffee Packaging Bags One-way valves, also known as degassing valves, are a critical component of coffee packaging bags, particularly for preserving the freshness of freshly roasted coffee beans. In this comprehensive explanation, we will delve into the mechanism, purpose, benefits, quality control, and sustainability aspects of one-way valves in coffee packaging bags.

Coffee Packaging Bags Mechanism of One-Way Valves:

The mechanism of one-way valves is ingeniously simple yet highly effective in preserving coffee freshness:

Coffee Packaging Bags Gas Release: After coffee beans are roasted, they continue to emit carbon dioxide (CO2) gas as a natural byproduct of the roasting process. This gas buildup can lead to overpressurization inside the bag.

Coffee Packaging Bags Threshold Opening: One-way valves are designed to open when the internal gas pressure reaches a specific threshold. This threshold is set to ensure that the valve opens only when necessary to release excess gas.

Coffee Packaging Bags Gas Escape: When the internal pressure exceeds the threshold, it forces the one-way valve to open, allowing the accumulated CO2 gas to escape through the valve.

Coffee Packaging Bags Air Exclusion: Importantly, the valve is designed to open only when the pressure from the inside exceeds a certain level. This prevents external air from entering the bag, preserving the coffee's freshness by preventing oxidation.

Coffee Packaging Bags Resealing: Once the excess gas has been released, the one-way valve automatically reseals, maintaining an airtight seal until the next release is needed.

Coffee Packaging Bags Purpose and Benefits of One-Way Valves:

The primary purpose of one-way valves in coffee packaging bags is to preserve the freshness, flavor, and aroma of coffee beans, especially after roasting. The benefits are multifaceted:

Coffee Packaging Bags Gas Release: One-way valves facilitate the controlled release of CO2 gas, preventing overpressurization that could damage the bag.

Coffee Packaging Bags Freshness Preservation: By preventing oxygen ingress, one-way valves help maintain the freshness and quality of coffee by reducing the risk of oxidation, staleness, and flavor degradation.

Coffee Packaging Bags Extended Shelf Life: Coffee beans can stay fresh for a more extended period when packaged with one-way valves, reducing waste and ensuring that consumers can enjoy the full flavor potential of their coffee.

Coffee Packaging Bags Reduced Packaging Stress: The accumulation of gas pressure within the bag can lead to structural stress on the bag, potentially causing leaks or ruptures. One-way valves prevent this stress.

Consumer Experience: Coffee lovers can trust that their coffee remains fresh between uses, enhancing the overall coffee experience.

Quality Control Measures:

Maintaining the quality and functionality of one-way valves is essential for their effectiveness:

Coffee Packaging Bags Valve Integrity: Manufacturers ensure that the one-way valve's diaphragm and sealing mechanism are of high quality and resistant to moisture and oils present in coffee beans.

Coffee Packaging Bags Opening Pressure: The opening pressure of the valve is precisely calibrated to release excess gas while keeping external air out. Quality control checks confirm that valves meet these specifications.

Seal Inspection: Manufacturers may employ automated systems to inspect the valves for defects, ensuring that they open and reseal as intended.

Coffee Packaging Bags Operator Training: Skilled operators are trained to monitor the valve integration process and make necessary adjustments to ensure consistent performance.

Coffee Packaging Bags Sustainability Aspects:

One-way valves align with sustainability efforts in coffee packaging:

Coffee Packaging Bags Reduced Waste: By extending the shelf life of coffee, one-way valves help reduce the frequency of coffee being discarded due to staleness, thus minimizing waste.

Coffee Packaging Bags Minimal Additional Packaging: One-way valves eliminate the need for other degassing methods, such as traditional vents or holes, which may require additional packaging materials.

In conclusion, one-way valves in coffee packaging bags play a vital role in preserving coffee freshness and quality. Their ingenious mechanism facilitates the controlled release of CO2 gas while preventing oxygen ingress, resulting in coffee that remains flavorful and aromatic. These valves have become a standard feature in specialty coffee packaging, ensuring that coffee enthusiasts can savor every cup at its best.

|  |

Airtight seals in coffee packaging bags are typically made from materials that offer excellent barrier properties and durability:

Aluminum Foil: Aluminum foil is commonly used as a component of coffee bag seals. It provides an excellent barrier against oxygen and moisture while also offering heat-sealing compatibility.

Polyethylene (PE) and Polypropylene (PP): These plastics are often used in zipper seals and as inner layers of coffee bags. They can be heat-sealed and offer good flexibility and resistance to moisture and gases.

Gasket Materials: Resealable coffee bags may incorporate specialized gasket materials, such as silicone or rubber, to ensure an airtight closure when the zipper is sealed.

The benefits of airtight seals in coffee packaging are numerous:

Preservation of Freshness: Airtight seals effectively preserve the coffee's flavor, aroma, and quality by preventing oxygen and moisture from degrading the beans.

Extended Shelf Life: Coffee beans can stay fresh for a more extended period in airtight packaging, reducing waste and ensuring consumers get the most out of their purchase.

Consumer Convenience: Resealable zipper seals make it easy for consumers to open and close the bag while maintaining freshness between uses.

Brand Reputation: Airtight packaging demonstrates a commitment to quality and freshness, enhancing a brand's reputation among coffee enthusiasts.

In conclusion, airtight seals in coffee packaging bags are essential for maintaining the integrity of coffee beans. They create a protective barrier that guards against oxygen and moisture, preserving the beans' freshness and flavor. With various mechanisms and materials at their disposal, coffee producers ensure that consumers can enjoy a premium coffee experience from the first sip to the last.

Address: Rm603. Yuanyang Building, No. 1008 of Heshan Avenue, Shaping, Jiangmen, Guangdong, China. Compostable coffee bags, biodegradable coffee bags, resealable coffee bags are made by coffee bags factory China